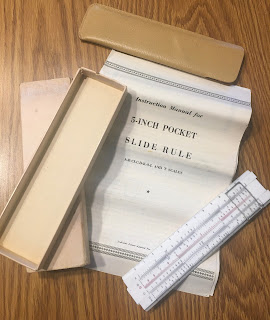

Quiz question! Who made the slide rule you see here? These are usually identified as Charles Bruning Co. rules, and we find them with the Bruning brand name on them.... but also Frederick Post, Dietzgen, Compass, Lietz, and others, and also completely unbranded as seen here. This one doesn't even say "Made in U.S.A." like they usually do. This is a 5 inch pocket model, but there also are 10 inch versions that look the same, and have the same brand names as above.

They are not made by Bruning, nor any of those other brand names either. They were made by a plastic injection molding company in Milwaukee, Wisconsin named PERELES BROS. INC. and their story is rather interesting.We have to go back to 1942 to pick up the trail of these slide rules. It was wartime, and all sorts of materials were restricted in the United States, just as in most other nations involved in the war. Plastics were not necessarily new then, but how they were being used was! Pereles Bros. had been using clear plastics to make aviator goggles, and one way or another (more on that in a subsequent page) they got into the drafting equipment manufacturing business.

It seems that the government needed drafting supplies and needed them fast, and expanding industry did too. Probably during 1942 Pereles began making such things.

A listing of expenditures by the U.S. Navy in 1942 indicates that over a million dollars were to be spent on such supplies, among other things such as triangles and triangular scales, so there was money being spent on these things for sure. Boxwood and mahogany needed weeks or months to cure before it could be used, so plastics were a great way to get around that time delay. A magazine put out internally by the plastics company Rohm and Haas, the Rohm and Haas Reporter, in 1943 announced the arrival of the new plastic items saying that: "New Drafting Instruments Demonstrate Precision in Plastics Molding: Slide rules by the thousands. Scales, protractors, and other drafting instruments by the tens of thousands-- all to meet the huge demand..." (Reporter 7) of wartime needs. We will see Rohm and Haas again in a minute, they had a big part in this project.

The November 1944 issue of the magazine Architectural Record announced the new plastic items with its own small article. "A complete line of all-plastic drafting instruments now being produced in quantity include a 5-in. pocket slide rule, a triangular relief facet scale for engineers, the same scale for architects, flat four-bevel scales, and two types of protractors.

"Special equipment and special methods are used to maintain a dimensional tolerance of .0005 in. per in. between lines as delicate as .003 to .0035 in. in width of graduations or calibrations, on the various instruments, and a depth of .005 in.

"Plastics used in the rules are Lucite, made by Du Pont, and Plexiglas, made by Rohm and Haas; Polystyrene made by Bakelite, Dow, or Monsanto. The 5in. types are of Lucite or Plexiglas and Polystyrene; the 10in. slide rules are entirely of Lucite or Plexiglas. Pereles Bros., Inc., Milwaukee, Wis." (Record 127-128)

The major accomplishment here was the use of raw powdered plastic product which was melted and injection molded and then cooled. The precision of Pereles' molds was unheard of, and the stability of the finished product was amazing even under conditions that would ruin a wood based slide rule. Scientific American magazine, in their January 1945 issue, had this to say: "Production of vitally needed drafting instruments has been materially increased through developments by Pereles Bros, Inc.. which makes possible greater accuracies in thermoplastic molding than ever before.

"All the instruments are being produced by the injection molding process, and several different types of plastic material are used. However, it is the accuracy and precision achieved by Pereles in the dies for the various instruments that has made their production possible. Using special equipment and special methods in its own engraving, tool, and die departments..." (Sci. Amer. 51-52) was what made the difference.

The publication Plastics and Resins 1944 had this to say: "... After numerous attempts to obtain dies with the necessary accuracies from outside engraving houses in Milwaukee, Chicago, and elsewhere, Pereles installed its own equipment to do the job. Many of the engravers contacted, said the work was impossible, while others who made the attempt were only able..." (Plastics and Resins 8) to achieve accuracies insufficient for such things as slide rules. So Pereles didn't just make some plastic slide rules and drafting equipment, they accomplished a whole new level of accuracy, precision, and stability in injection molding! "... Pereles officials believe they have opened the way for widespread expansion in many other fields." (Plastics and Resins 36)

Okay, let's look at a few examples. Scroll back up and look at the boxed example above, that has no branding whatsoever. Such sets are partly to blame for these rules having always been attributed to Bruning, because the instructions with early rules were written and published by Bruning, who was probably with Dietzgen in being the first RETAIL DISTRIBUTORS of Pereles made drafting equipment, including but not limited to slide rules, which are of course our focus.

At left we see a tiny imprint on the instructions of the set in the photo we are talking about, and this says Copyright 1944 CBCO which stands for Charles Bruning and Co. But this is for the instructions, not the slide rule! Pereles probably had no hand in generating slide rule instructions, they did enough in making these slide rules!Now some sets of Dietzgen branded Pereles 5" slide rules have instructions with a 1942 date in them, but it is not at all certain that these sets were sold to the public in 1942. Early production probably went all to the military.

At left is such a set, with a cursor like that seen on wood WW2 slide rules, and note that this slide rule has the K scale on the top stator, not the bottom. I can tell you this though, the name "Redi-Rule" was trademarked by Dietzgen, and on the file at the USPTO it states that the first USE of the name Redi-Rule was July 29, 1944. We do see rules from Dietzgen like that at left, with no model number 1771 on them and not saying Redi-Rule, which seems to indicate that these rules are prior to July 1944. At any rate, Dietzgen, Bruning, AND Post seem to have been early buyers.

|

Above are two of the 10 inch types, which are actually fairly common because Lucite and Plexiglas do not outgas and destroy themselves like the celluloid organic plastic materials do! If you have a rule made of either of these, shine a flashlight through from behind it! I have not seen any 10 inch rules made of Polystyrene but who knows. They may be out there! The 5 inch can be either, as we will see.

|

No comments:

Post a Comment